One Stop Solutions Since 1959

Jet Processing has been providing one stop solutions for chemical processing, surface treatments, testing, and assembly of precision metal components since 1959. We welcome the opportunity to become a valued member of your production team. Please contact us to request a quote and to learn how we can help grow your business by satisfying all of your special process treatment needs.

Multiple Capabilities Add Value

Our comprehensive range of treatments and processes include NDT, Anodizing, Chemical Conversion Coatings, Passivation, Solid Film Lubricant, Painting, Pressure Testing, and Assembly Services. Also part marking enables us to reduce our customer’s cost and add value to the products, providing reduced lead times and rapid turnaround.

Visit our documents to find PCC's comprehensive capabilities in metal finishing. We work together to provide you with the best solution.

New Technology

Our commitment to continuous improvement in our quest for perfection is reflected in our investment in a state-of-the-art facility and equipment. This commitment helps to ensure a quality product, on time, at a competitive price, regardless of the project scale or schedule.

Customer Service Every Step Of The Way

Our dedicated customer service representatives are here to support you, from the quoting stage to shipping of the finished product. Whether providing a progress report, answering technical questions or a fulfilling a special request, we are here to ensure your total satisfaction.

PCC acquired Jet Processing with Noranco in July, 2015.

Jet offers a comprehensive range of treatments and processes including:Â

Chemical Processing

Anodize on Aluminum Alloys

Chromic Acid-Type

- Class 1 (Neutral Color)

- Class 2Â (Black,Blue, Brown, Green, Gold, Red Violet, Grey Teal)

Sulfuric Acid-Type II

- Class 1 (Neutral Color)

- Class 2 (Black, Blue, Brown, Green, Gold, Red, Violet, Grey, Teal)

Hard Anodize Type III

- Class 1 (Neutral Color)

- Class 2 (Black, Blue, Brown, Green, Gold, Red, Violet, Grey, Teal)

- Teflon Impregnation

Conversion Coating Aluminum Alloys

- Class 1A Hexavalent Type 1

- Class 3 Trivalent Type II

Passivation of Stainless Steels

- Type II- Nitric/Sodium Dichromate

- Type VI- Nitric Acid

- Type VIII- Nitric Acid

Conventional Spray Painting

- Epoxy & Urethane Primers

- Epoxy & Urethane Top Coats

- Chemical Agent Resistant Coating (CARC)

- Lacquers

- High Temperature Enamels

- Marking Paints and DyesÂ

- Silk Screen Printing

Dry Film Lubricants

- Teflon Dispersion Coating

Pressure Flush

- Impregnation of Castings

Jet Passivation

Jet Waxing

Lab Services

- Corrosion Resistance: Water Immersion, Salt Fog, Copper Sulfate

- Taber Abrasion Resistance

- Coating Weight

- Coefficient of Friction

- Solution Analysis

- Millipore Inspection

- Electrical Resistance of Conversion Coatings

Non Destructive Testing

- Liquid Penetrant Inspect (LPI)

- Magnetic Particle Inspect (MPI)

- Pressure Test

- ImpregnationÂ

Assembly

Jet offers added value by providing a large variety of hardware assembly, and part marking services. Among the many assembly services we provide are, installation of helical thread inserts, Pins, Plugs, Studs, Bearings, Bushings, Rivets, etc.

Jet Assembly

Jet Magnetic-Particle

Products

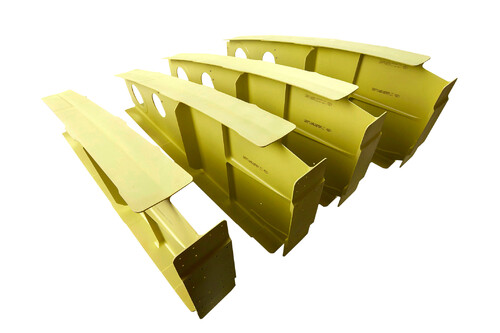

- Structural Assemblies

- Blocker Doors

- Truss Ribs

- Bulkheads

- Fan Cowl Support Beams

- Splice Ribs

| Process | Sub-Processes | Customer | Specs |

|---|---|---|---|

| Painting & Coatings | Chemical Conversion Coating - ty I | Aerojet Rocketdyne | MIL-C-5541 |

| Non-Destructive Testing | Penetrant Inspection | Aerojet Rocketdyne | ASTM-E-1417 |

| Miscellaneous | Adhesive Primer Control (QPL) | Boeing | HP4-100 |

| Anodizing | Anodize - Chromic | Boeing | HP 4-2 |

| Anodizing | Anodize - Chromic | Boeing | PS13201 |

| Anodizing | Anodize - Hard | Boeing | HP 4-35 (finish 19 of EPB 4-230) |

| Anodizing | Anodize - Hard | Boeing | HP 4-68 ty III, cl 1 |

| Anodizing | Anodize - Hard | Boeing | HP 4-79 |

| Anodizing | Anodize - Hard | Boeing | PS13208 |

| Anodizing | Anodize - Sulfuric | Boeing | HP 4-2 |

| Anodizing | Anodize - Sulfuric | Boeing | MIL-A-8625 |

| Anodizing | Anodize - Sulfuric | Boeing | PS13201 |

| Anodizing | Anodizing - Aluminum (QPL) | Boeing | HP4-2 |

| Anodizing | Anodizing Aluminum | Boeing | PS13201 |

| Anodizing | Anodizing Aluminum - Metal to Metal Bonding (QPL) | Boeing | HP4-35 |

| Anodizing | Anodizing Aluminum - Wear Resistance (QPL) | Boeing | HP4-79 |

| Miscellaneous | Boeing Approved QMS | Boeing | Quality System |

| Painting & Coatings | Chemical Conversion Coating - ty I | Boeing | HP 4-57 - immersion only |

| Painting & Coatings | Chemical Conversion Coating - ty I | Boeing | MIL-C-5541 - immersion only |

| Painting & Coatings | Chemical Conversion Coating - ty I | Boeing | MIL-DTL-5541 - immersion only |

| Painting & Coatings | Chemical Conversion Coating - ty I | Boeing | PS13209 |

| Painting & Coatings | Chemical Conversion Coating on Aluminum | Boeing | MIL-C-5541 |

| Painting & Coatings | Chemical Conversion Coatings on Aluminum Alloys | Boeing | MIL-DTL-5541 |

| Painting & Coatings | Chemical Film - Aluminum | Boeing | MIL-A-8625 |

| Anodizing | Chromic Acid Anodizing | Boeing | DPS11.01 |

| Anodizing | Chromic Acid Anodizing - Chromate Sealed | Boeing | DPS11.01-3 |

| Anodizing | Chromic Acid Anodizing of Alum. - Type I | Boeing | MIL-A-8625 |

| Pretreatment | Cleaning/Etch | Boeing | C 106 |

| Pretreatment | Cleaning/Etch | Boeing | C 129 |

| Pretreatment | Cleaning/Etch | Boeing | C 5098 |

| Pretreatment | Cleaning/Etch | Boeing | C 7129 |

| Pretreatment | Cleaning/Etch | Boeing | EMS 92427 |

| Pretreatment | Cleaning/Etch | Boeing | FI-1811 |

| Pretreatment | Cleaning/Etch | Boeing | HP 9-24 |

| Pretreatment | Cleaning/Etch | Boeing | LHP 6014 |

| Pretreatment | Cleaning/Etch | Boeing | PC 5022 |

| Non-Destructive Testing | Flourocarbon Impregnation - Inorganic Coatings (QPL) | Boeing | HP4-68 |

| Anodizing | Hard Anodize Type III | Boeing | MIL-A-8625 |

| Anodizing | Hard Anodizing - Class 1 and 2 | Boeing | BAC 5821 |

| Painting & Coatings | Hard Coat - Aluminum | Boeing | PS13208 |

| Non-Destructive Testing | Liquid Penetrant Inspection | Boeing | BSS 7039 |

| Painting & Coatings | Multicolored Chemical Conversion of Aluminum Alloys | Boeing | PS13209 |

| Non-Destructive Testing | NDI Personnel Cert level 3 Penetrant | Boeing | MIL-STD-410 |

| Non-Destructive Testing | NDI Personnel Cert level 3 Penetrant | Boeing | NAS 410 |

| Non-Destructive Testing | NDI Personnel Certification Level 3 Magnetic | Boeing | NAS 410 |

| Non-Destructive Testing | NDI Personnel Certification Level 3 Penetrant | Boeing | NAS 410 |

| Non-Destructive Testing | NDI Personnel Certification Level 3 Penetrant | Boeing | MIL-STD-410 |

| Non-Destructive Testing | Penetrant Inspection | Boeing | BAC 5423 |

| Non-Destructive Testing | Penetrant Inspection | Boeing | ASTM-E-1417 |

| Non-Destructive Testing | Penetrant Inspection | Boeing | PS 21202 (alumininum; stainless steel; titanium) |

| Non-Destructive Testing | Penetrant Inspection - Aluminum | Boeing | PS21202 |

| Non-Destructive Testing | Penetrant Inspection - Fluorescent (QPL) | Boeing | HP6-13 |

| Non-Destructive Testing | Penetrant Inspection - Stainless Steels | Boeing | PS21202 |

| Non-Destructive Testing | Penetrant Inspection - Titanium | Boeing | PS21202 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Boeing | HP 4-100 |

| Non-Destructive Testing | Process Solution Control | Boeing | Chem. Testing |

| Non-Destructive Testing | Salt Spray Testing | Boeing | ASTM-B-117 |

| Anodizing | Sulfuric Acid Anodize Type II | Boeing | MIL-A-8625 |

| Anodizing | Sulfuric Acid Anodizing | Boeing | BAC 5022 |

| Anodizing | Anodize - Chromic | Eaton | MIL-A-8625 |

| Anodizing | Anodize - Chromic | Eaton | VS 1-3-1-3 |

| Anodizing | Anodize - Hard | Eaton | MIL-A-8625 |

| Anodizing | Anodize - Hard | Eaton | VS 1-3-1-4 |

| Anodizing | Anodize - Hard | Eaton | VS 1-3-1-62 |

| Anodizing | Anodize - Hard | Eaton | VS 1-3-5-104 |

| Anodizing | Anodize - Sulfuric | Eaton | MIL-A-8625 |

| Anodizing | Anodize - Sulfuric | Eaton | VS 1-3-1-1 |

| Anodizing | Anodize - Sulfuric | Eaton | VS 1-3-1-2 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Eaton | MIL-DTL-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Eaton | VS 1-3-1-8 |

| Pretreatment | Passivation | Eaton | AMS 2700 |

| Pretreatment | Passivation | Eaton | VS 1-3-1-15 |

| Non-Destructive Testing | Penetrant Inspection | Eaton | ASTM-E-1417 |

| Non-Destructive Testing | Penetrant Inspection | Eaton | VS 1-3-5-289 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Eaton | MIL-L-46010 |

| Anodizing | Anodize - Chromic | GE | PS 102 |

| Anodizing | Anodize - Sulfuric | GE | PS 102 |

| Pretreatment | Passivation | GE | PS 124 |

| Non-Destructive Testing | Penetrant Inspection | GE | NDT 8 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | GE | PS 117 |

| Anodizing | Anodize - Chromic | Hamilton Sundstrand | MIL-A-8625 |

| Anodizing | Anodize - Chromic | Hamilton Sundstrand | CPS 1000 |

| Anodizing | Anodize - Hard | Hamilton Sundstrand | MIL-A-8625 |

| Anodizing | Anodize - Sulfuric | Hamilton Sundstrand | MIL-A-8625 |

| Anodizing | Anodize - Sulfuric | Hamilton Sundstrand | CPS 1000 |

| Anodizing | Anodize - Sulfuric | Hamilton Sundstrand | HS 334 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Hamilton Sundstrand | MIL-C-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Hamilton Sundstrand | MIL-DTL-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Hamilton Sundstrand | HS 240 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Hamilton Sundstrand | PN 14.12 |

| Pretreatment | Passivation | Hamilton Sundstrand | AMS 2700 |

| Non-Destructive Testing | Penetrant Inspection | Hamilton Sundstrand | ASTM-E-1417 |

| Non-Destructive Testing | Penetrant Inspection | Hamilton Sundstrand | PN 16.03 |

| Non-Destructive Testing | Penetrant Inspection | Hamilton Sundstrand | PS 21202 |

| Anodizing | Anodize - Chromic | Honeywell | AMS 2470 |

| Anodizing | Anodize - Chromic | Honeywell | MIL-A-8625 |

| Anodizing | Anodize - Chromic | Honeywell | PS-1025 |

| Anodizing | Anodize - Chromic | Honeywell | M 8261241 |

| Anodizing | Anodize - Hard | Honeywell | AMS 2468 |

| Anodizing | Anodize - Hard | Honeywell | AMS 2469 |

| Anodizing | Anodize - Hard | Honeywell | AMS 2482 |

| Anodizing | Anodize - Hard | Honeywell | EMS 52401 |

| Anodizing | Anodize - Hard | Honeywell | EMS 52456 |

| Anodizing | Anodize - Hard | Honeywell | ES-0725 (HC-0 and HC-2 only) |

| Anodizing | Anodize - Hard | Honeywell | ES-1364 |

| Anodizing | Anodize - Hard | Honeywell | GPS 3205-1 |

| Anodizing | Anodize - Hard | Honeywell | M 692441 |

| Anodizing | Anodize - Hard | Honeywell | MIL-A-63576 |

| Anodizing | Anodize - Hard | Honeywell | MIL-A-8625 |

| Anodizing | Anodize - Hard | Honeywell | M 8261241 |

| Anodizing | Anodize - Sulfuric | Honeywell | AMS 2471 |

| Anodizing | Anodize - Sulfuric | Honeywell | AMS 2472 |

| Anodizing | Anodize - Sulfuric | Honeywell | FI-1153 |

| Anodizing | Anodize - Sulfuric | Honeywell | M 69527 (finish 27) |

| Anodizing | Anodize - Sulfuric | Honeywell | MIL-A-8625 |

| Anodizing | Anodize - Sulfuric | Honeywell | M 8261241 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | AMS-C-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | AMS 2473 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | AMS 2474 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | AMS 2477 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | ES-0598 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | GPS 3200-1 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | M 690278 (finish 40, 40A) |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | MIL-C-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | MIL-DTL-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | M 8258211 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | AMS-M-3171 (ty I, III, IV, VI, VII, VIII) |

| Painting & Coatings | Chemical Conversion Coating - ty I | Honeywell | MIL-M-3171 (ty I, III, IV, VI, VII, VIII) |

| Painting & Coatings | Dry Film Lube | Honeywell | AMS 2515 |

| Painting & Coatings | Dry Film Lube | Honeywell | AMS 2525 |

| Painting & Coatings | Dry Film Lube | Honeywell | AS 5272 |

| Painting & Coatings | Dry Film Lube | Honeywell | EMS 52402 (I, B, C; IV, B; ty I; ty XIII) |

| Painting & Coatings | Dry Film Lube | Honeywell | EMS 92382 |

| Painting & Coatings | Dry Film Lube | Honeywell | ES-0704 |

| Painting & Coatings | Dry Film Lube | Honeywell | ES-1303 |

| Painting & Coatings | Dry Film Lube | Honeywell | ES-1996 |

| Painting & Coatings | Dry Film Lube | Honeywell | FI-1093 |

| Painting & Coatings | Dry Film Lube | Honeywell | FI-1164 |

| Painting & Coatings | Dry Film Lube | Honeywell | Fi-1170 |

| Painting & Coatings | Dry Film Lube | Honeywell | FI-1190 |

| Painting & Coatings | Dry Film Lube | Honeywell | FI-1231 |

| Painting & Coatings | Dry Film Lube | Honeywell | FI-1287 |

| Painting & Coatings | Dry Film Lube | Honeywell | Fi-1517 |

| Painting & Coatings | Dry Film Lube | Honeywell | FP 5044 |

| Painting & Coatings | Dry Film Lube | Honeywell | FP 7088 |

| Painting & Coatings | Dry Film Lube | Honeywell | GPS 3211-1 |

| Painting & Coatings | Dry Film Lube | Honeywell | GPS 3250-1 |

| Painting & Coatings | Dry Film Lube | Honeywell | GPS 7313-1 |

| Painting & Coatings | Dry Film Lube | Honeywell | HPS 1020 |

| Painting & Coatings | Dry Film Lube | Honeywell | M 692024 |

| Painting & Coatings | Dry Film Lube | Honeywell | MIL-L-46010 (ty I, II) |

| Painting & Coatings | Dry Film Lube | Honeywell | MIL-L-8937 |

| Painting & Coatings | Dry Film Lube | Honeywell | MIL-PRF-46010 |

| Painting & Coatings | Dry Film Lube | Honeywell | MIL-PRF-81329 |

| Pretreatment | Passivation | Honeywell | AMS-QQ-P-35 (ty II, VI, VII, VIII) |

| Pretreatment | Passivation | Honeywell | AMS 2700 (ty 1-8) |

| Pretreatment | Passivation | Honeywell | ASTM-A-380 |

| Pretreatment | Passivation | Honeywell | ASTM-A-967 |

| Pretreatment | Passivation | Honeywell | C 5041 (cl I, II) |

| Pretreatment | Passivation | Honeywell | ES-091 |

| Pretreatment | Passivation | Honeywell | GPS 3000-1 (cl 1) |

| Pretreatment | Passivation | Honeywell | M 69510 |

| Pretreatment | Passivation | Honeywell | QQ-P-35 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | AMS 2645 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | AMS 2646 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | ASTM-E-1417 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | EMS 52309 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | EMS 72358 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | EMS 92358 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | ES-0680 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | GPS 5103-1 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | GPS 7325-1 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | HGS 1010 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | LHP 8037 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | M 694669 |

| Non-Destructive Testing | Penetrant Inspection | Honeywell | MIL-STD-6866 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | AMS2510 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | EMS 92382 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 5025 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 5073 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 5074 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 5104 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 5109 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 5110 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 7073 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 7074 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 7076 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 7077 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 7078 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 7080 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 7081 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 7083 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 7089 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | GPS 3300-1 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | GPS 3301-1 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | GPS 7310-1 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | HPS 1010 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | M 2595289 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | M 4030956 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | M 4065816 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | MIL-C-22751 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | MIL-C-81907 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | MIL-DTL-18264 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | MIL-DTL-53072 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | MIL-F-14072 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | MIL-F-18264 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | MIL-STD-1303 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | MIL-STD-171 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 133 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | FP 134 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | GPS 7009-1 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | GPS 7010-1 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | LHP 5709 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | LHP 5710 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Honeywell | M 8251332 |

| Anodizing | Anodize - Chromic | Lockheed Martin | MIL-A-8625 |

| Anodizing | Anodize - Chromic | Lockheed Martin | AMS 2470 |

| Anodizing | Anodize - Hard | Lockheed Martin | MIL-A-8625 |

| Anodizing | Anodize - Hard | Lockheed Martin | MIL-A-63576 |

| Anodizing | Anodize - Hard | Lockheed Martin | AMS 2468 |

| Anodizing | Anodize - Hard | Lockheed Martin | AMS 2469 |

| Anodizing | Anodize - Hard | Lockheed Martin | AMS 2482 |

| Anodizing | Anodize - Sulfuric | Lockheed Martin | MIL-A-8625 |

| Anodizing | Anodize - Sulfuric | Lockheed Martin | AMS 2471 |

| Anodizing | Anodize - Sulfuric | Lockheed Martin | AMS 2472 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Lockheed Martin | MIL-DTL-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Lockheed Martin | MIL-C-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Lockheed Martin | AMS 2473 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Lockheed Martin | ASTM-B-449 cl 1, 2, 4 |

| Painting & Coatings | Chemical Conversion Coating - ty II | Lockheed Martin | MIL-DTL-5541 |

| Pretreatment | Passivation | Lockheed Martin | AMS 2700 |

| Pretreatment | Passivation | Lockheed Martin | AMS-QQ-P-35 |

| Pretreatment | Passivation | Lockheed Martin | ASTM-A-380 |

| Pretreatment | Passivation | Lockheed Martin | ASTM-A-967 (nit 2) |

| Non-Destructive Testing | Penetrant Inspection | Lockheed Martin | ASTM-E-1417 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Lockheed Martin | 7999070 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Lockheed Martin | MIL-DTL-53072 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Lockheed Martin | MIL-PRF-46010 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Lockheed Martin | AMS 2515 |

| Non-Destructive Testing | Salt Spray Testing | Lockheed Martin | ASTM-B-117 |

| Anodizing | Anodize - Chromic | MD Helicopter | MDP 4-2 |

| Anodizing | Anodize - Hard | MD Helicopter | MDP 4-68 (cl 1 PTFE) |

| Anodizing | Anodize - Hard | MD Helicopter | MDP 4-79 |

| Anodizing | Anodize - Hard | MD Helicopter | MDP 4-35 |

| Anodizing | Anodize - Sulfuric | MD Helicopter | MDP 4-2 |

| Painting & Coatings | Chemical Conversion Coating - ty I | MD Helicopter | MDP 4-57 |

| Pretreatment | Cleaning/Etch | MD Helicopter | MDP 9-24 |

| Pretreatment | Cleaning/Etch | MD Helicopter | MDP 9-25 (ty I, cl 3 and ty II, cl 2 & 3) |

| Pretreatment | Cleaning/Etch | MD Helicopter | MDP 9-5 |

| Pretreatment | Passivation | MD Helicopter | MDP 4-8 |

| Non-Destructive Testing | Penetrant Inspection | MD Helicopter | MDP 6-13 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MD Helicopter | MDP 4-107 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MD Helicopter | MDP 4-100 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MD Helicopter | MDP 4-28 |

| Anodizing | Anodize - Chromic | MOOG | MIL-A-8625 |

| Anodizing | Anodize - Hard | MOOG | MIL-A-8625 |

| Anodizing | Anodize - Hard | MOOG | MIL-A-63576 |

| Anodizing | Anodize - Hard | MOOG | AMS 2468 |

| Anodizing | Anodize - Sulfuric | MOOG | MIL-A-8625 |

| Painting & Coatings | Chemical Conversion Coating - ty I | MOOG | MIL-C-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | MOOG | MIL-DTL-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | MOOG | AMS 2473 |

| Pretreatment | Passivation | MOOG | QQ-P-35 (ty II, VI) |

| Pretreatment | Passivation | MOOG | ASTM-A-380 |

| Non-Destructive Testing | Penetrant Inspection | MOOG | ASTM-E-1417 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | AMS 2515 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-C-8514 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-C-22750 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-C-46168 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-C-83286 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-C-85285 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-F-7179 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-F-18264 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-L-23398 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-L-46010 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-L-81329 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-L-8937 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-P-23377 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-P-53022 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-P-53030 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | MOOG | MIL-P-85582 |

| Anodizing | Anodize - Chromic | Northrop Grumman | 2ZZP00001 (ty IV/IC) |

| Anodizing | Anodize - Sulfuric | Northrop Grumman | 2ZZP00001 (ty IB/IC) |

| Anodizing | Anodize - Sulfuric | Northrop Grumman | MIL-A-8625 (ty II, IIB) |

| Painting & Coatings | Chemical Conversion Coating - ty I | Northrop Grumman | MIL-DTL-5541 |

| Pretreatment | Cleaning/Etch | Northrop Grumman | GP 17G |

| Pretreatment | Cleaning/Etch | Northrop Grumman | GSS 7015 |

| Pretreatment | Cleaning/Etch | Northrop Grumman | MPD 1074 |

| Pretreatment | Passivation | Northrop Grumman | AMS 2700 |

| Non-Destructive Testing | Penetrant Inspection | Northrop Grumman | ACS-PRS-7005 |

| Non-Destructive Testing | Penetrant Inspection | Northrop Grumman | ASTM-E-1417 |

| Non-Destructive Testing | Penetrant Inspection | Northrop Grumman | GT 23 A |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Northrop Grumman | AMS-C-27725 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Northrop Grumman | GSS 14600 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Northrop Grumman | GSS 4306 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Northrop Grumman | GSS 4310 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Northrop Grumman | GSS 4510 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | Northrop Grumman | LMA-PJ264 |

| Non-Destructive Testing | Salt Spray Testing | Northrop Grumman | ASTM-B-117 |

| Anodizing | Anodize - Chromic | Safran | MIL-A-8625 |

| Anodizing | Anodize - Sulfuric | Safran | MIL-A-8625 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Safran | MIL-DTL-5541 |

| Pretreatment | Passivation | Safran | AMS 2700 |

| Non-Destructive Testing | Penetrant Inspection | Safran | ASTM-E-1417 |

| Non-Destructive Testing | Penetrant Inspection | Safran | PCS 3200 |

| Anodizing | Anodize - Chromic | SpaceX | MIL-A-8625 |

| Anodizing | Anodize - Hard | SpaceX | MIL-A-8625 |

| Anodizing | Anodize - Hard | SpaceX | MIL-A-63576 |

| Anodizing | Anodize - Hard | SpaceX | AMS 2482 |

| Anodizing | Anodize - Sulfuric | SpaceX | MIL-A-8625 |

| Painting & Coatings | Chemical Conversion Coating - ty I | SpaceX | MIL-DTL-5541 |

| Pretreatment | Cleaning/Etch | SpaceX | NASA PRC 5010 |

| Painting & Coatings | Dry Film Lube | SpaceX | MIL-PRF-46010 |

| Painting & Coatings | Dry Film Lube | SpaceX | AS 5272 |

| Pretreatment | Passivation | SpaceX | AMS 2700 |

| Pretreatment | Passivation | SpaceX | ASTM-A-380/A380M - 13) |

| Non-Destructive Testing | Penetrant Inspection | SpaceX | NDT-PT-00035468 (annex A only) |

| Non-Destructive Testing | Penetrant Inspection | SpaceX | ASTM-E-1417 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | SpaceX | MIL-PRF-85285 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | SpaceX | SPX-00036701 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | SpaceX | MIL-PRF-18264 |

| Anodizing | Anodize - Chromic | ULA | MIL-A-8625 |

| Anodizing | Anodize - Chromic | ULA | AMS 2470 (ty I) |

| Anodizing | Anodize - Hard | ULA | MIL-A-8625 |

| Anodizing | Anodize - Hard | ULA | AMS 2469 (ty III) |

| Anodizing | Anodize - Hard | ULA | MIL-A-63576 |

| Anodizing | Anodize - Hard | ULA | AMS 2482 |

| Anodizing | Anodize - Hard | ULA | AMS 2468 (ty III) |

| Anodizing | Anodize - Hard | ULA | 5-75148-5 |

| Anodizing | Anodize - Sulfuric | ULA | MIL-A-8625 |

| Anodizing | Anodize - Sulfuric | ULA | AMS 2471 (ty II) |

| Anodizing | Anodize - Sulfuric | ULA | AMS 2472 |

| Anodizing | Anodize - Sulfuric | ULA | 5-75148-1 - thru -4 |

| Painting & Coatings | Chemical Conversion Coating - ty I | ULA | EPS 30063 |

| Painting & Coatings | Chemical Conversion Coating - ty I | ULA | MIL-C-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | ULA | MIL-DTL-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | ULA | 5-75141 |

| Painting & Coatings | Chemical Conversion Coating - ty I | ULA | AMS 2473 |

| Painting & Coatings | Chemical Conversion Coating - ty I | ULA | ASTM-B-449 (cl 1-4) |

| Pretreatment | Cleaning/Etch | ULA | ASTM-A-380 |

| Painting & Coatings | Dry Film Lube | ULA | MIL-PRF-46010 |

| Painting & Coatings | Dry Film Lube | ULA | 0-75343 |

| Painting & Coatings | Dry Film Lube | ULA | 0-74068 |

| Pretreatment | Passivation | ULA | AMS-QQ-P-35 |

| Pretreatment | Passivation | ULA | ASTM-A-967 (nitric 2) |

| Pretreatment | Passivation | ULA | AMS 2700 |

| Non-Destructive Testing | Penetrant Inspection | ULA | 5-75174 |

| Non-Destructive Testing | Penetrant Inspection | ULA | ASTM-E-1417 |

| Painting & Coatings | Primer / Bond Primer / Fuel tank Coating / Topcoat | ULA | MIL-F-18264 |

| Anodizing | Anodize - Sulfuric | Woodward | MIL-A-8625 |

| Anodizing | Anodize - Sulfuric | Woodward | SP-822 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Woodward | SP-870 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Woodward | MIL-C-5541 |

| Painting & Coatings | Chemical Conversion Coating - ty I | Woodward | MIL-DTL-5541 |

| Non-Destructive Testing | Penetrant Inspection | Woodward | SP-916 |

Can't find your spec? Please contact us.

Supplier Quality Documents

| Title | Notes |

|---|---|

| Pickering - Purchase Order Quality Clauses | NORW-054 - Rev. C |

| Supplier Quality System Questionnaire | AQS1001 - Rev. B |

| Supplier Quality Requirements Manual | SQR10000 - Rev. E |

PCC Aerostructures Document Library

View documents for all of our PCC Aerostructures sites including Terms and Conditions, Quality Certificates, and Supplier Documents.

Quality Certificates

We believe quality is the responsibility of our complete workforce; therefore, we build quality into the product from the moment it is received to final shipping. Our dedicated team of highly skilled quality personnel take great pride in adhering to the stringent compliance requirements of the many standards, specifications, and procedures demanded by our customers.

- Nadcap Approved

- AS9100 Compliant

Address:

2632 W. Quail Ave.

Phoenix, AZ 85027

Phone:Â (623) 869-6749

Fax:Â (623) 869-9771